・Broad Band Chirped Mirror with Negative GDD

・Broad Band Chirped Mirror with Negative GDD and TOD

・Chirped Mirror for 800nm The fundamental of Ti-sapphire laser

・Chirped Mirror for UV The second harmonics of Ti-sapphire laser

・GTI Laser Mirror GDD= ‐1000fs2 For femtosecond lasers

・Low Dispersion Mirror

・High Power Laser Mirror

・Dual Wavelength Mirror for High Power Lasers

・Ultra Broad Band Mirror

・Ultra High Reflectance Mirror

Broad Band Chirped Mirror with Negative GDD

“Application : Pulse compensation of femtosecond laser beam

Feature : Wide band, Dispersion,Flat GDD (<0)

Dispersion compensation in wide wavelength is an important technology for obtaining an ultrashort pulse with the pulse width less than 10fs.

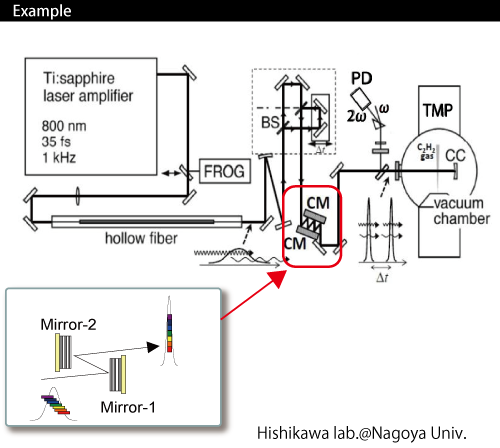

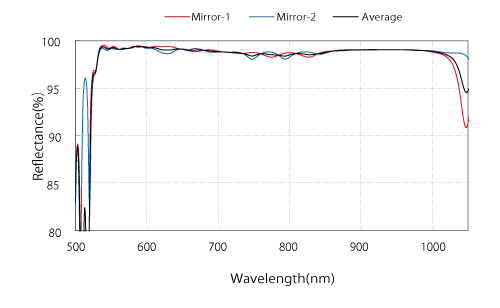

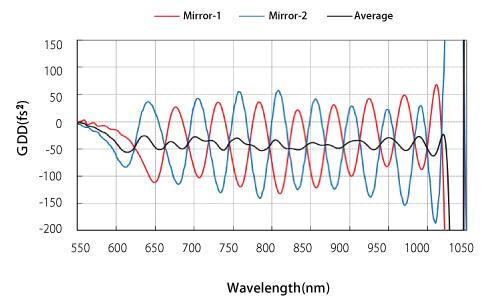

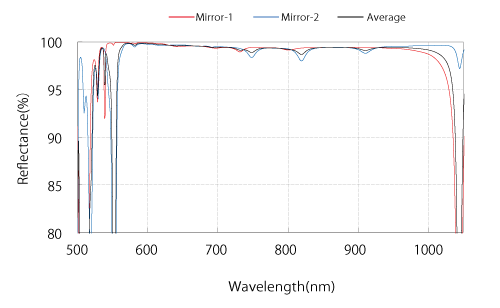

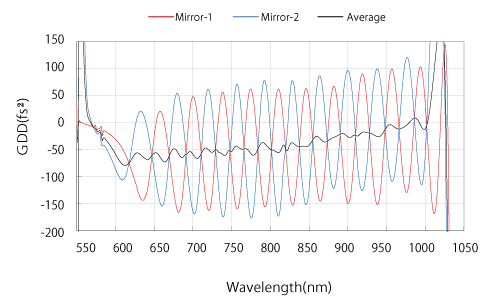

A dielectric multilayer mirror can be used for this purpose, if its reflective phase, φ , is properly adjusted to the intended system. For up-chirped pulse, negative group delay dispersion (GDD), – ∂ 2 φ / ∂ ω2, is required. We have designed two kinds of chirped mirrors, which cancel each other oscillation of GDD in order to obtain a nearly flat negative GDD as a function of wavelength. Some features of the mirrors are a constant negative GDD and high reflectance for wavelengths between 600nm-1000nm.

Broad Band Chirped Mirror with Negative GDD and TOD

Application : Pulse compensation of femtosecond laser beam

Feature : Wide band, Dispersion compensation up to 3rd order

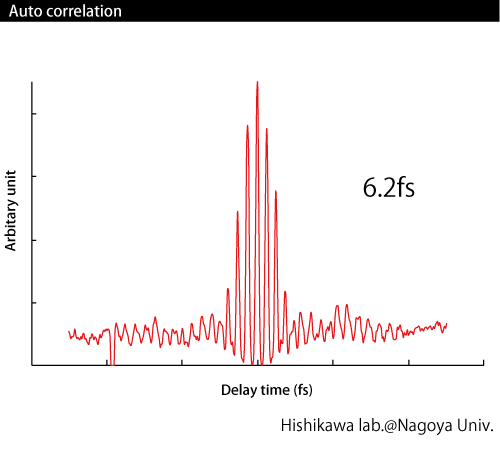

For precise control of the pulse shape, higher order dispersion compensation is required. Since, in general, group velocity dispersion (GVD) of mediums is large at shorter wavelengths, larger negative GDD is expected for chirped mirrors. This chirped mirror has been designed to compensate for GVD up to the 3rd order dispersion (TOD), – ∂3 φ / ∂ ω3, where GDD<0 and TOD<0. By using these mirrors in combination with the mirrors listed in P5, pulses with wide spectral width broaden by self phase modulation are compressed to 6.2fs (almost Fourier transformation limit). Measured auto correlation is shown in the right graph.

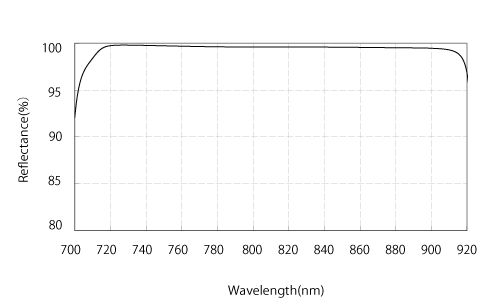

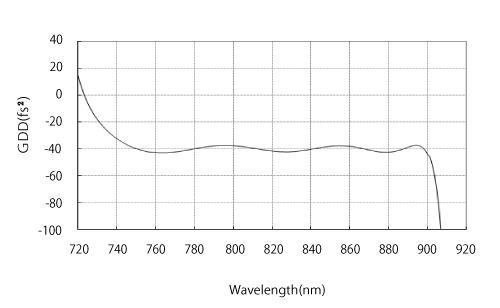

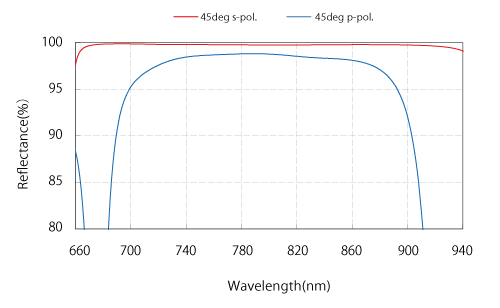

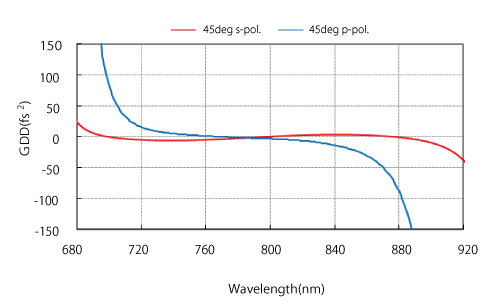

Chirped Mirror for 800nm The fundamental of Ti-sapphire laser

Application : Pulse compensation of femtosecond laser beam

Feature : High reflectance

This chirped mirror is design for the dispersion compensation of up-chirped pulses with wavelengths around 800nm. Some features of this mirror are a constant negative GDD and high reflectance for wavelengths between 750nm-850nm. The mirror coated on the rectangular substrate is also listed, which will be helpful to obtain large amount of GDD by multiple reflections between two opposite mirrors.

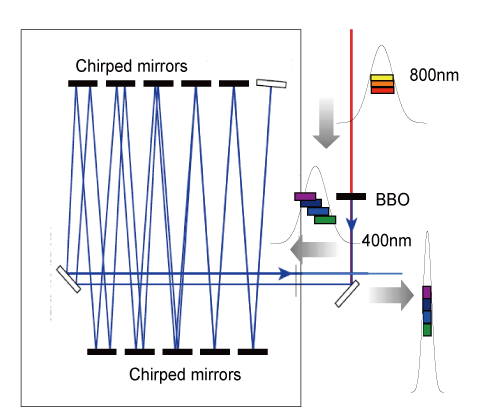

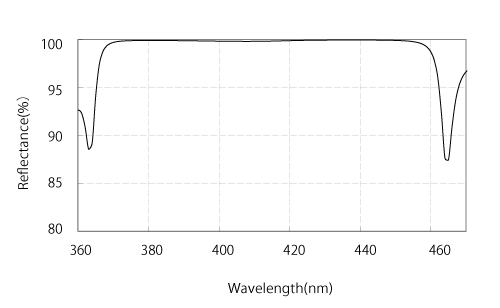

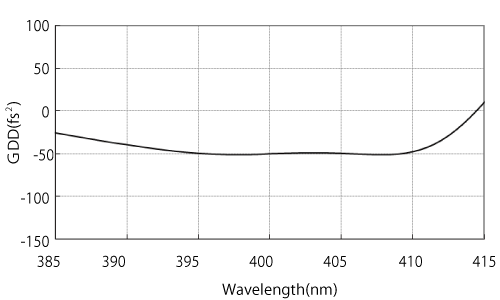

Chirped Mirror for UV The second harmonics of Ti-sapphire laser

Application : Pulse compensation of UV femtosecond laser beam

Feature : High reflectance and dispersion compensation in UV region

Dispersion compensation is an important technology in the Ti-Sapphire laser systems. In the molecular science, there are many cases where the second harmonics of the ultrashort pulses are used. In these cases, careful attention is required for larger dispersion of the group velocity of medium in the ultraviolet (UV) region. With this in mind and through the collaboration with Hishikawa lab. of Nagoya University, this chirped mirror has been developed for the sake of the dispersion compensation in the UV region.

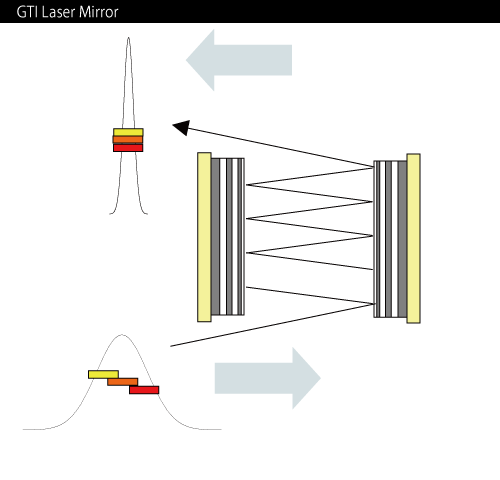

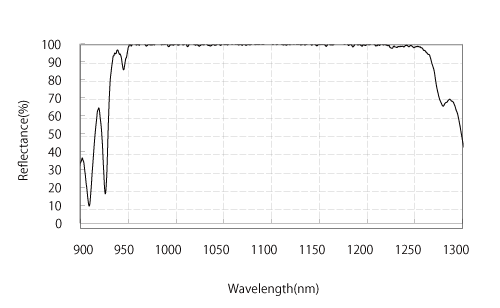

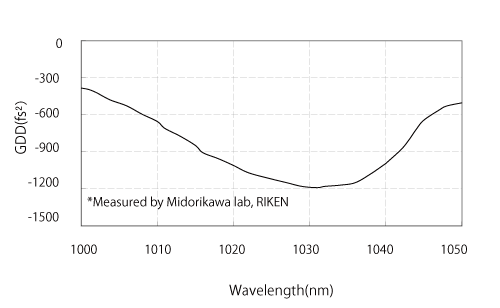

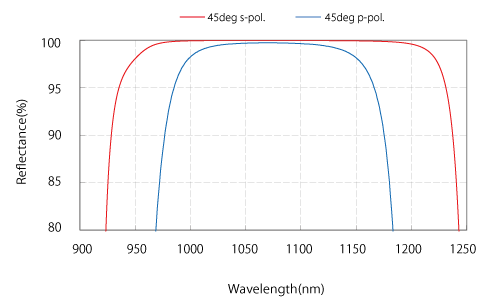

GTI Laser Mirror GDD= ‐1000fs2 For femtosecond lasers

Application : Pulse compensation of femtosecond laser beam

Feature : Large group delay dispersion(GDD) and low optical loss

This Gires-Tournois-Interferometer (GTI) laser mirror is designed for the dispersion compensation of up-chirped pulses with wavelengths around 1030nm. The main features of this mirror are large negative GDD and low optical loss accomplished by the ion beam sputtering coating process.

This mirror has been applied for the Kerr lens mode-locked thin-disk ring oscillator, and has been contributed to generate femtosecond laser pulses with an intra cavity peak power beyond 100MW (*1)

(*1) A. Amani Eilanlou, Yasuo Nabekawa, Makoto Kuwata-Gonokami and Katsumi Midorikawa Japanese Journal of Applied Physics 53, 082701(2014)

Low Dispersion Mirror

Application : Turning mirror for ultra short pulses

Feature : Low dispersion and high reflectance

Femtosecond pulses are easily broadened and lose their high intensity peak when they propagate in mediums or are reflected by standard multilayer mirrors. This leads to difficulty with utilizing the femtosecond pulses’high peak during use. This mirror is designed to reduce changes in pulse shape through reflection. The result is shown in the image to the right. The short pulse sustains the sharpness even after changing its propagating direction from this mirror. Energy loss can be reduced compared to that of metal mirrors.

High Power Laser Mirror

Application : High power laser systems

Feature : High laser induced damage threshold

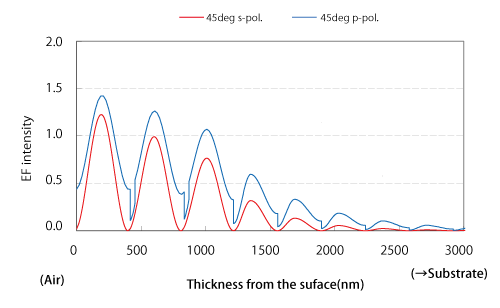

In high power laser systems, multilayer mirrors are required to have high laser induced damage threshold (LIDT), since damage to the mirrors prevents increasing the output energy of the system. To make a mirror’s LIDT high, our mirrors are designed by taking into account the distribution of the electric field (EF) formed by incident laser beams in the mirrors.

The right figure shows standing waves of EF in a mirror for 1064nm. The intensities are normalized by the intensity of incident waves. The standing waves originate in the interference between propagating waves and reflected waves from respective boundaries, where waves in orthogonal polarization states are independent of each other. In general, the intensities became large near the incident medium. It had been pointed out that if the strong intensity peaks are located at boundaries, the mirror is easily broken down by high powered laser beams(*1 *2).

For the sake of application for high power laser systems, our mirrors are optimized to shift the EF intensity peaks from boundaries (shown by vertical dotted line), keeping high reflectance for the wave.

(*1)B.E. Newman, S.R. Folty, L.J. Jolin and C.K. Carniglia, Laser Induced Damage in Optical Materials:1981”, NBS Spec. Publ.638, p.3 63

(*2) Y. Sato, M. Kobiyama, S. Kimura and S. Tamura: daikoshi kiho, 39-4, p156 (1988) (in Japanese)

Dual Wavelength Mirror for High Power Lasers

Application : Second harmonic generation, High power laser systems

Feature : High laser induced damage threshold for 1064nm and 532nm

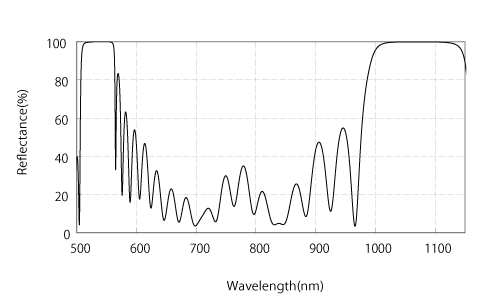

Recently, two high-power laser beams with different wavelength are often used simultaneously in an optical system. For example, the laser beams are Nd:YAG fundamental wave (1064nm) and its second harmonic wave (532nm) generated by the wavelength conversion technique. The optics used in the system, such as multilayer mirrors and optical thin film filters, are expected to have complex spectral reflectance and/or transmittance as well as the resistance for high powered laser beams.

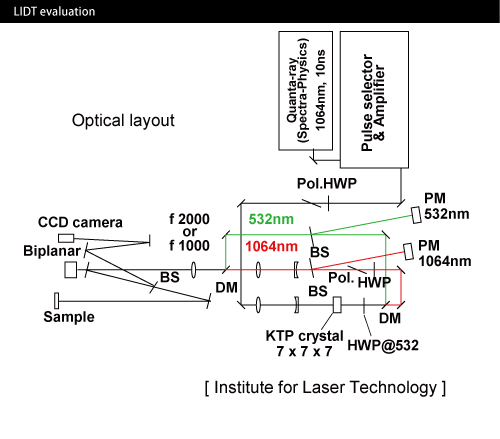

We propose dual wavelength mirror with high laser induced damage thresholds (LIDT) for both 1064nm and 532nm, where this mirror is designed by extending the conventional design method. The high LIDTs of this mirror have been confirmed experimentally by the Institute of Laser Technology.

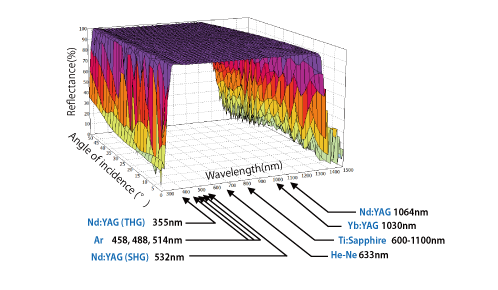

Ultra Broad Band Mirror

Application : Harmonics of Nd:YAG laser,gas laser,etc.,

Feature : High reflectance at wide AOI in wide wavelength

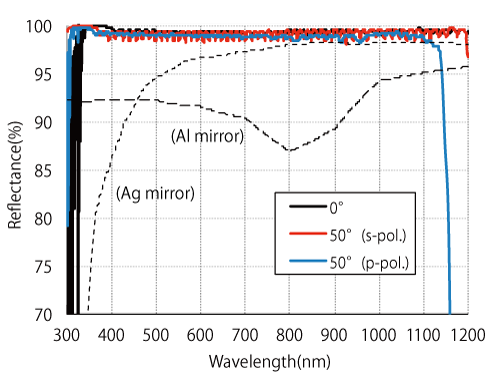

This mirror is constructed by dielectric materials with over 200 layers. Since the film quality is very high as a result of applying ion beam sputtering to the coating process, the optical loss is very low regardless of the film’s high thickness. The main feature of this mirror is to have high reflectance for wide wavelengths and a wide angle of incidence regardless of the polarization. This mirror will allow greater flexibility when constructing laser systems.

For reference, the spectral reflectance is compared to that of an Ag mirror and Al mirror in the right graph.

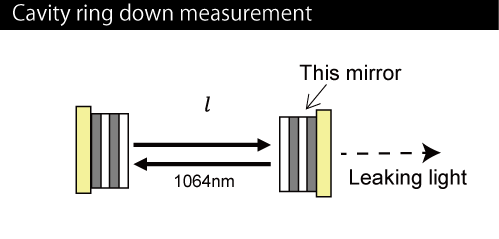

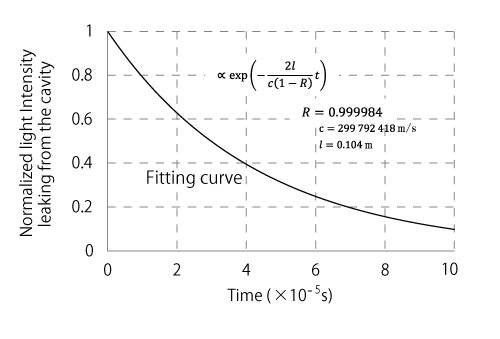

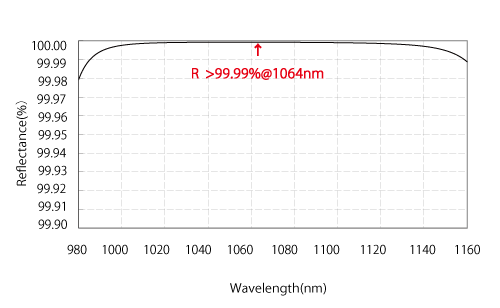

Ultra High Reflectance Mirror

Application : Pulse compensation of femtosecond laser beam

Feature : Wide band, Dispersion,Flat GDD (<0)

Dispersion compensation in wide wavelength is an important technology for obtaining an ultrashort pulse with the pulse width less than 10fs.

A dielectric multilayer mirror can be used for this purpose, if its reflective phase, φ , is properly adjusted to the intended system. For up-chirped pulse, negative group delay dispersion (GDD), – ∂ 2 φ / ∂ ω2, is required. We have designed two kinds of chirped mirrors, which cancel each other oscillation of GDD in order to obtain a nearly flat negative GDD as a function of wavelength. Some features of the mirrors are a constant negative GDD and high reflectance for wavelengths between 600nm-1000nm.

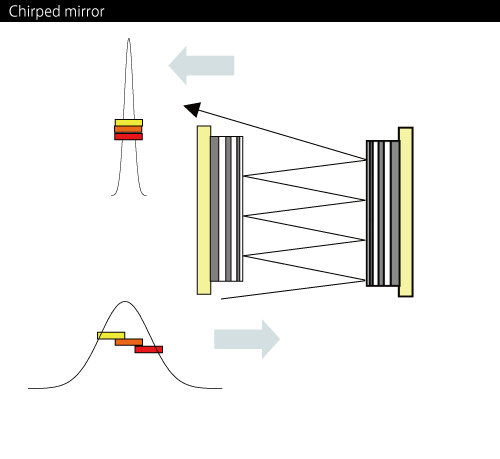

Chirped Mirror

Chirped Mirror

Dispersion compensation mirror for optical system.

Multi-Wavelenth Laser Mirror

Multi-Wavelenth Laser Mirror

Many Kinds of laser lights can be reflected by this single mirror